descridomain_7 3d surfaces on engineering drawings

An engineering cartoon is a type of technical cartoon that is used to convey information about an object. A common apply is to specify the geometry necessary for the structure of a component and is chosen a detail drawing. Usually, a number of drawings are necessary to completely specify even a simple component. The drawings are linked together past a master drawing or assembly cartoon which gives the drawing numbers of the subsequent detailed components, quantities required, construction materials and possibly 3D images that tin can be used to locate individual items. Although by and large consisting of pictographic representations, abbreviations and symbols are used for brevity and additional textual explanations may also be provided to convey the necessary information.

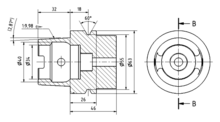

The process of producing engineering drawings is often referred to every bit technical drawing or drafting (draughting).[1] Drawings typically comprise multiple views of a component, although additional scratch views may exist added of details for further explanation. Only the information that is a requirement is typically specified. Key information such equally dimensions is commonly merely specified in one place on a drawing, avoiding redundancy and the possibility of inconsistency. Suitable tolerances are given for critical dimensions to allow the component to be manufactured and function. More detailed production drawings may be produced based on the information given in an engineering cartoon. Drawings have an information box or title block containing who drew the cartoon, who canonical it, units of dimensions, meaning of views, the title of the drawing and the drawing number.

History [edit]

Technical cartoon has existed since ancient times. Complex technical drawings were made in renaissance times, such equally the drawings of Leonardo da Vinci. Mod applied science drawing, with its precise conventions of orthographic project and scale, arose in France at a time when the Industrial Revolution was in its infancy. 50. T. C. Rolt'due south biography of Isambard Kingdom Brunel[2] says of his father, Marc Isambard Brunel, that "It seems adequately certain that Marc's drawings of his block-making machinery (in 1799) made a contribution to British technology technique much greater than the machines they represented. For information technology is rubber to assume that he had mastered the art of presenting three-dimensional objects in a two-dimensional plane which nosotros now call mechanical drawing. It had been evolved past Gaspard Monge of Mezieres in 1765 but had remained a military secret until 1794 and was therefore unknown in England."[2]

Standardization and disambiguation [edit]

Engineering drawings specify requirements of a component or assembly which can be complicated. Standards provide rules for their specification and interpretation. Standardization also aids internationalization, because people from different countries who speak different languages can read the aforementioned engineering drawing, and interpret it the same way.

One major set of engineering cartoon standards is ASME Y14.5 and Y14.5M (virtually recently revised in 2009). These apply widely in the U.s.a., although ISO 8015 (Geometrical product specifications (GPS) — Fundamentals — Concepts, principles and rules) is at present as well of import.

In 2011, a new revision of ISO 8015 (Geometrical production specifications (GPS) — Fundamentals — Concepts, principles and rules) was published containing the Invocation Principle. This states that, "In one case a portion of the ISO geometric product specification (GPS) arrangement is invoked in a mechanical engineering science production documentation, the entire ISO GPS system is invoked." Information technology also goes on to state that marking a drawing "Tolerancing ISO 8015" is optional. The implication of this is that any drawing using ISO symbols tin only exist interpreted to ISO GPS rules. The only style not to invoke the ISO GPS organisation is to invoke a national or other standard. U.k., BS 8888 (Technical Product Specification) has undergone of import updates in the 2010s.

Media [edit]

For centuries, until the 1970s, all engineering drawing was done manually by using pencil and pen on paper or other substrate (e.1000., vellum, mylar). Since the appearance of computer-aided pattern (CAD), engineering drawing has been done more and more than in the electronic medium with each passing decade. Today most engineering drawing is done with CAD, but pencil and newspaper have non entirely disappeared.

Some of the tools of manual drafting include pencils, pens and their ink, straightedges, T-squares, French curves, triangles, rulers, protractors, dividers, compasses, scales, erasers, and tacks or push pins. (Slide rules used to number among the supplies, besides, but nowadays even transmission drafting, when it occurs, benefits from a pocket calculator or its onscreen equivalent.) And of course the tools too include drawing boards (drafting boards) or tables. The English idiom "to go dorsum to the drawing lath", which is a figurative phrase pregnant to rethink something altogether, was inspired by the literal act of discovering blueprint errors during production and returning to a drawing board to revise the engineering drawing. Drafting machines are devices that aid manual drafting past combining drawing boards, straightedges, pantographs, and other tools into one integrated drawing environment. CAD provides their virtual equivalents.

Producing drawings usually involves creating an original that is so reproduced, generating multiple copies to be distributed to the shop floor, vendors, company archives, and so on. The classic reproduction methods involved blue and white appearances (whether white-on-blue or bluish-on-white), which is why engineering science drawings were long called, and even today are still often called, "blueprints" or "bluelines", even though those terms are anachronistic from a literal perspective, since well-nigh copies of engineering drawings today are fabricated by more than modern methods (frequently inkjet or light amplification by stimulated emission of radiation printing) that yield black or multicolour lines on white newspaper. The more generic term "print" is now in common usage in the U.S. to mean any newspaper re-create of an engineering drawing. In the case of CAD drawings, the original is the CAD file, and the printouts of that file are the "prints".

Systems of dimensioning and tolerancing [edit]

Almost all engineering drawings (except maybe reference-simply views or initial sketches) communicate not only geometry (shape and location) but also dimensions and tolerances[1] for those characteristics. Several systems of dimensioning and tolerancing have evolved. The simplest dimensioning system merely specifies distances between points (such as an object's length or width, or hole eye locations). Since the advent of well-developed interchangeable manufacture, these distances have been accompanied by tolerances of the plus-or-minus or min-and-max-limit types. Coordinate dimensioning involves defining all points, lines, planes, and profiles in terms of Cartesian coordinates, with a common origin. Coordinate dimensioning was the sole best option until the post-World War II era saw the development of geometric dimensioning and tolerancing (GD&T), which departs from the limitations of coordinate dimensioning (east.g., rectangular-merely tolerance zones, tolerance stacking) to permit the well-nigh logical tolerancing of both geometry and dimensions (that is, both class [shapes/locations] and sizes).

Common features [edit]

Drawings convey the following disquisitional information:

- Geometry – the shape of the object; represented equally views; how the object will look when information technology is viewed from various angles, such as front end, tiptop, side, etc.

- Dimensions – the size of the object is captured in accustomed units.

- Tolerances – the allowable variations for each dimension.

- Material – represents what the detail is fabricated of.

- Finish – specifies the surface quality of the particular, functional or cosmetic. For example, a mass-marketed product usually requires a much college surface quality than, say, a component that goes inside industrial machinery.

Line styles and types [edit]

Standard engineering drawing line types

A multifariousness of line styles graphically represent concrete objects. Types of lines include the following:

- visible – are continuous lines used to draw edges directly visible from a item angle.

- hidden – are short-dashed lines that may be used to represent edges that are not directly visible.

- center – are alternately long- and short-dashed lines that may exist used to represent the axes of circular features.

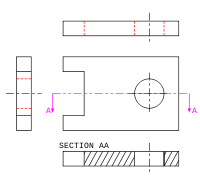

- cut plane – are sparse, medium-dashed lines, or thick alternately long- and double short-dashed that may exist used to define sections for section views.

- section – are thin lines in a pattern (blueprint determined by the material being "cut" or "sectioned") used to bespeak surfaces in section views resulting from "cutting". Section lines are commonly referred to as "cantankerous-hatching".

- phantom – (not shown) are alternately long- and double short-dashed thin lines used to stand for a feature or component that is not role of the specified part or assembly. Eastward.thousand. barracks ends that may be used for testing, or the machined production that is the focus of a tooling cartoon.

Lines tin also be classified by a letter classification in which each line is given a letter.

- Type A lines show the outline of the feature of an object. They are the thickest lines on a drawing and done with a pencil softer than HB.

- Type B lines are dimension lines and are used for dimensioning, projecting, extending, or leaders. A harder pencil should be used, such as a 2H pencil.

- Type C lines are used for breaks when the whole object is not shown. These are freehand drawn and only for curt breaks. 2H pencil

- Type D lines are similar to Type C, except these are zigzagged and only for longer breaks. 2H pencil

- Blazon E lines indicate hidden outlines of internal features of an object. These are dotted lines. 2H pencil

- Blazon F lines are Type East lines, except these are used for drawings in electrotechnology. 2H pencil

- Blazon G lines are used for centre lines. These are dotted lines, but a long line of 10–xx mm, then a 1 mm gap, then a pocket-size line of 2 mm. 2H pencil

- Type H lines are the same as type One thousand, except that every 2nd long line is thicker. These signal the cutting aeroplane of an object. 2H pencil

- Type G lines bespeak the alternate positions of an object and the line taken by that object. These are drawn with a long line of x–xx mm, then a small-scale gap, then a small line of 2 mm, then a gap, then another small line. 2H pencil.

Multiple views and projections [edit]

Paradigm of a role represented in beginning-angle project

Symbols used to define whether a projection is either first-angle (left) or 3rd-bending (correct).

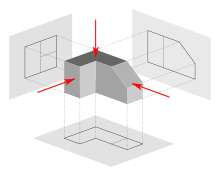

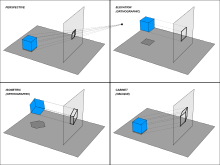

Several types of graphical projection compared

Diverse projections and how they are produced

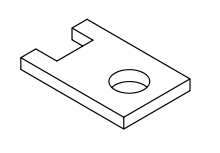

Isometric view of the object shown in the applied science drawing below.

In nearly cases, a single view is non sufficient to evidence all necessary features, and several views are used. Types of views include the following:

Multiview projection [edit]

A multiview projection is a type of orthographic project that shows the object equally it looks from the front, correct, left, top, bottom, or dorsum (e.g. the chief views), and is typically positioned relative to each other co-ordinate to the rules of either showtime-angle or 3rd-angle projection. The origin and vector direction of the projectors (also chosen projection lines) differs, as explained below.

- In first-angle projection, the parallel projectors originate as if radiated from behind the viewer and pass through the 3D object to projection a 2nd epitome onto the orthogonal plane backside it. The 3D object is projected into 2nd "paper" space equally if you were looking at a radiograph of the object: the top view is under the front end view, the right view is at the left of the front view. First-bending project is the ISO standard and is primarily used in Europe.

- In third-bending projection, the parallel projectors originate every bit if radiated from the far side of the object and laissez passer through the 3D object to project a second image onto the orthogonal plane in front of information technology. The views of the 3D object are like the panels of a box that envelopes the object, and the panels pivot as they open up up flat into the plane of the drawing.[3] Thus the left view is placed on the left and the top view on the tiptop; and the features closest to the front end of the 3D object volition appear closest to the front view in the drawing. Third-angle projection is primarily used in the U.s.a. and Canada, where it is the default projection arrangement according to ASME standard ASME Y14.3M.

Until the tardily 19th century, kickoff-angle project was the norm in North America equally well equally Europe;[4] [5] but circa the 1890s, third-angle projection spread throughout the North American engineering and manufacturing communities to the point of condign a widely followed convention,[iv] [v] and it was an ASA standard by the 1950s.[five] Circa World War I, British practice was often mixing the use of both projection methods.[iv]

As shown to a higher place, the conclusion of what surface constitutes the front end, dorsum, top, and lesser varies depending on the projection method used.

Non all views are necessarily used.[6] Generally only as many views are used as are necessary to convey all needed data conspicuously and economically.[vii] The front, elevation, and right-side views are usually considered the core group of views included by default,[eight] but any combination of views may be used depending on the needs of the detail blueprint. In addition to the six principal views (front, back, top, bottom, right side, left side), whatsoever auxiliary views or sections may be included as serve the purposes of role definition and its advice. View lines or section lines (lines with arrows marked "A-A", "B-B", etc.) define the management and location of viewing or sectioning. Sometimes a notation tells the reader in which zone(s) of the drawing to find the view or section.

Auxiliary views [edit]

An auxiliary view is an orthographic view that is projected into whatever plane other than one of the six primary views.[9] These views are typically used when an object contains some sort of inclined plane. Using the auxiliary view allows for that inclined plane (and whatsoever other significant features) to exist projected in their true size and shape. The truthful size and shape of any characteristic in an engineering drawing can only exist known when the Line of Sight (LOS) is perpendicular to the aeroplane being referenced. It is shown like a three-dimensional object. Auxiliary views tend to make use of axonometric projection. When existing all by themselves, auxiliary views are sometimes known as pictorials.

Isometric projection [edit]

An isometric projection shows the object from angles in which the scales forth each axis of the object are equal. Isometric projection corresponds to rotation of the object by ± 45° most the vertical axis, followed by rotation of approximately ± 35.264° [= arcsin(tan(30°))] about the horizontal axis starting from an orthographic project view. "Isometric" comes from the Greek for "same measure". One of the things that makes isometric drawings and then attractive is the ease with which 60° angles can be synthetic with but a compass and straightedge.

Isometric projection is a blazon of axonometric projection. The other two types of axonometric projection are:

- Dimetric projection

- Trimetric projection

Oblique projection [edit]

An oblique projection is a simple type of graphical projection used for producing pictorial, 2-dimensional images of three-dimensional objects:

- it projects an prototype by intersecting parallel rays (projectors)

- from the three-dimensional source object with the drawing surface (projection programme).

In both oblique projection and orthographic projection, parallel lines of the source object produce parallel lines in the projected paradigm.

Perspective projection [edit]

Perspective is an guess representation on a apartment surface, of an image every bit it is perceived by the eye. The 2 almost feature features of perspective are that objects are fatigued:

- Smaller as their distance from the observer increases

- Foreshortened: the size of an object'south dimensions along the line of sight are relatively shorter than dimensions beyond the line of sight.

Section Views [edit]

Projected views (either Auxiliary or Multiview) which show a cross section of the source object forth the specified cut plane. These views are commonly used to show internal features with more clarity than may exist available using regular projections or hidden lines. In assembly drawings, hardware components (e.thou. basics, screws, washers) are typically not sectioned. Section view is a one-half side view of object.

Scale [edit]

Plans are commonly "calibration drawings", meaning that the plans are drawn at specific ratio relative to the bodily size of the identify or object. Various scales may be used for different drawings in a ready. For example, a floor plan may be drawn at ane:50 (1:48 or one⁄four ″ = 1′ 0″) whereas a detailed view may be fatigued at ane:25 (1:24 or 1⁄ii ″ = 1′ 0″). Site plans are oft drawn at 1:200 or 1:100.

Scale is a nuanced discipline in the use of engineering drawings. On i manus, it is a general principle of engineering drawings that they are projected using standardized, mathematically certain projection methods and rules. Thus, swell effort is put into having an engineering science drawing accurately depict size, shape, form, aspect ratios between features, and and so on. And yet, on the other hand, there is another full general principle of engineering drawing that nearly diametrically opposes all this effort and intent—that is, the principle that users are non to scale the cartoon to infer a dimension not labeled. This stern admonition is often repeated on drawings, via a boilerplate note in the title cake telling the user, "Exercise NOT Scale DRAWING."

The explanation for why these 2 almost opposite principles tin can coexist is every bit follows. The outset principle—that drawings volition exist made and so advisedly and accurately—serves the prime goal of why engineering drawing fifty-fifty exists, which is successfully communicating role definition and credence criteria—including "what the office should wait like if yous've made it correctly." The service of this goal is what creates a drawing that one even could scale and get an accurate dimension thereby. And thus the great temptation to do so, when a dimension is wanted but was not labeled. The 2nd principle—that even though scaling the drawing will usually work, one should nevertheless never do it—serves several goals, such as enforcing total clarity regarding who has authority to discern design intent, and preventing erroneous scaling of a cartoon that was never fatigued to scale to begin with (which is typically labeled "drawing not to calibration" or "calibration: NTS"). When a user is forbidden from scaling the drawing, s/he must plough instead to the engineer (for the answers that the scaling would seek), and s/he will never erroneously scale something that is inherently unable to be accurately scaled.

But in some ways, the advent of the CAD and MBD era challenges these assumptions that were formed many decades ago. When part definition is divers mathematically via a solid model, the assertion that one cannot interrogate the model—the direct analog of "scaling the cartoon"—becomes ridiculous; considering when part definition is divers this mode, it is non possible for a drawing or model to exist "non to scale". A 2D pencil drawing tin can be inaccurately foreshortened and skewed (and thus not to scale), yet however exist a completely valid office definition as long as the labeled dimensions are the only dimensions used, and no scaling of the drawing past the user occurs. This is because what the drawing and labels convey is in reality a symbol of what is wanted, rather than a true replica of information technology. (For example, a sketch of a pigsty that is conspicuously non round still accurately defines the role as having a true round hole, as long as the label says "10mm DIA", considering the "DIA" implicitly but objectively tells the user that the skewed fatigued circle is a symbol representing a perfect circle.) Only if a mathematical model—essentially, a vector graphic—is declared to be the official definition of the part, then whatsoever amount of "scaling the cartoon" can make sense; there may still be an error in the model, in the sense that what was intended is non depicted (modeled); simply at that place tin be no error of the "non to scale" blazon—because the mathematical vectors and curves are replicas, non symbols, of the part features.

Even in dealing with 2D drawings, the manufacturing world has inverse since the days when people paid attending to the scale ratio claimed on the impress, or counted on its accuracy. In the by, prints were plotted on a plotter to verbal scale ratios, and the user could know that a line on the drawing 15mm long corresponded to a 30mm part dimension because the drawing said "1:ii" in the "scale" box of the title cake. Today, in the era of ubiquitous desktop printing, where original drawings or scaled prints are often scanned on a scanner and saved as a PDF file, which is then printed at any per centum magnification that the user deems handy (such as "fit to paper size"), users have pretty much given up caring what scale ratio is claimed in the "scale" box of the championship block. Which, under the rule of "exercise not calibration drawing", never actually did that much for them anyhow.

Showing dimensions [edit]

Sizes of drawings [edit]

Sizes of drawings typically comply with either of two unlike standards, ISO (World Standard) or ANSI/ASME Y14.1 (American).

The metric cartoon sizes correspond to international newspaper sizes. These developed further refinements in the 2d half of the twentieth century, when photocopying became inexpensive. Engineering drawings could exist readily doubled (or halved) in size and put on the next larger (or, respectively, smaller) size of paper with no waste of space. And the metric technical pens were called in sizes and then that 1 could add detail or drafting changes with a pen width irresolute by approximately a factor of the foursquare root of ii. A full set up of pens would accept the following nib sizes: 0.xiii, 0.18, 0.25, 0.35, 0.5, 0.7, 1.0, 1.5, and 2.0 mm. However, the International Organization for Standardization (ISO) called for four pen widths and set a colour code for each: 0.25 (white), 0.35 (yellow), 0.5 (brown), 0.seven (blueish); these nibs produced lines that related to various text character heights and the ISO newspaper sizes.

All ISO paper sizes have the aforementioned attribute ratio, i to the square root of 2, pregnant that a document designed for any given size tin can exist enlarged or reduced to whatever other size and volition fit perfectly. Given this ease of irresolute sizes, it is of course common to copy or print a given document on dissimilar sizes of paper, especially within a series, east.thousand. a cartoon on A3 may be enlarged to A2 or reduced to A4.

The U.Southward. customary "A-size" corresponds to "letter" size, and "B-size" corresponds to "ledger" or "tabloid" size. There were likewise one time British paper sizes, which went past names rather than alphanumeric designations.

American Lodge of Mechanical Engineers (ASME) ANSI/ASME Y14.ane, Y14.2, Y14.3, and Y14.5 are ordinarily referenced standards in the U.Southward.

Technical lettering [edit]

Technical lettering is the process of forming letters, numerals, and other characters in technical drawing. Information technology is used to describe, or provide detailed specifications for an object. With the goals of legibility and uniformity, styles are standardized and lettering ability has little relationship to normal writing ability. Engineering science drawings use a Gothic sans-serif script, formed by a series of curt strokes. Lower instance letters are rare in most drawings of machines. ISO Lettering templates, designed for use with technical pens and pencils, and to arrange ISO paper sizes, produce lettering characters to an international standard. The stroke thickness is related to the character height (for instance, ii.5mm high characters would take a stroke thickness - pen beak size - of 0.25mm, iii.5 would use a 0.35mm pen then forth). The ISO character set (font) has a seriffed one, a barred 7, an open four, six, and nine, and a round topped three, that improves legibility when, for instance, an A0 drawing has been reduced to A1 or even A3 (and perchance enlarged back or reproduced/faxed/ microfilmed &c). When CAD drawings became more popular, especially using US American software, such as AutoCAD, the nearest font to this ISO standard font was Romantic Simplex (RomanS) - a proprietary shx font) with a manually adjusted width cistron (over ride) to make information technology wait as virtually to the ISO lettering for the drawing lath. All the same, with the closed four, and arced six and nine, romans.shx typeface could be difficult to read in reductions. In more recent revisions of software packages, the TrueType font ISOCPEUR reliably reproduces the original drawing board lettering stencil style, however, many drawings take switched to the ubiquitous Arial.ttf.

Conventional parts (areas) [edit]

Title block [edit]

Every technology drawing must take a title cake.[10] [xi] [12]

The title cake (T/B, TB) is an area of the drawing that conveys header-type information nigh the cartoon, such equally:

- Drawing title (hence the proper name "title cake")

- Drawing number

- Part number(due south)

- Name of the pattern activity (corporation, authorities bureau, etc.)

- Identifying lawmaking of the design action (such equally a Cage code)

- Accost of the design activity (such as city, land/province, land)

- Measurement units of the drawing (for example, inches, millimeters)

- Default tolerances for dimension callouts where no tolerance is specified

- Boilerplate callouts of general specs

- Intellectual holding rights warning

ISO 7200 specifies the data fields used in title blocks. Information technology standardizes viii mandatory information fields:[thirteen]

- Title (hence the proper name "title block")

- Created by (proper noun of draughtsman)

- Canonical past

- Legal owner (proper name of company or organization)

- Document blazon

- Drawing number (same for every canvas of this document, unique for each technical document of the organisation)

- Sheet number and number of sheets (for example, "Sheet 5/vii")

- Date of issue (when the drawing was made)

Traditional locations for the title block are the bottom right (most commonly) or the height correct or center.

Revisions block [edit]

The revisions block (rev cake) is a tabulated list of the revisions (versions) of the cartoon, documenting the revision control.

Traditional locations for the revisions block are the top right (most commonly) or bordering the title block in some way.

Side by side assembly [edit]

The next assembly block, often besides referred to as "where used" or sometimes "effectivity block", is a list of higher assemblies where the product on the electric current drawing is used. This block is usually found next to the title block.

Notes list [edit]

The notes list provides notes to the user of the drawing, conveying any information that the callouts within the field of the drawing did non. It may include general notes, flagnotes, or a mixture of both.

Traditional locations for the notes list are anywhere along the edges of the field of the drawing.

General notes [edit]

General notes (G/N, GN) utilize by and large to the contents of the cartoon, every bit opposed to applying just to certain part numbers or sure surfaces or features.

Flagnotes [edit]

Flagnotes or flag notes (FL, F/N) are notes that employ only where a flagged callout points, such equally to item surfaces, features, or part numbers. Typically the callout includes a flag icon. Some companies call such notes "delta notes", and the note number is enclosed inside a triangular symbol (similar to capital letter delta, Δ). "FL5" (flagnote five) and "D5" (delta annotation v) are typical ways to abbreviate in ASCII-merely contexts.

Field of the drawing [edit]

The field of the drawing (F/D, FD) is the main torso or main area of the drawing, excluding the title block, rev block, P/L and then on

Listing of materials, bill of materials, parts listing [edit]

The listing of materials (L/Chiliad, LM, LoM), nib of materials (B/M, BM, BoM), or parts listing (P/L, PL) is a (usually tabular) list of the materials used to make a part, and/or the parts used to make an assembly. It may contain instructions for oestrus treatment, finishing, and other processes, for each function number. Sometimes such LoMs or PLs are separate documents from the drawing itself.

Traditional locations for the LoM/BoM are above the title cake, or in a separate document.

Parameter tabulations [edit]

Some drawings telephone call out dimensions with parameter names (that is, variables, such a "A", "B", "C"), then tabulate rows of parameter values for each part number.

Traditional locations for parameter tables, when such tables are used, are floating near the edges of the field of the drawing, either virtually the title block or elsewhere along the edges of the field.

Views and sections [edit]

Each view or section is a separate set of projections, occupying a contiguous portion of the field of the cartoon. Usually views and sections are chosen out with cross-references to specific zones of the field.

Zones [edit]

Oftentimes a drawing is divided into zones by an alphanumeric grid, with zone labels forth the margins, such as A, B, C, D up the sides and 1,2,3,iv,5,6 along the pinnacle and lesser.[14] Names of zones are thus, for example, A5, D2, or B1. This characteristic greatly eases give-and-take of, and reference to, particular areas of the drawing.

Abbreviations and symbols [edit]

Every bit in many technical fields, a wide array of abbreviations and symbols have been developed in engineering drawing during the 20th and 21st centuries. For example, cold rolled steel is often abbreviated equally CRS, and diameter is oft abbreviated equally DIA, D, or ⌀.

Most engineering drawings are language-independent—words are bars to the title block; symbols are used in place of words elsewhere.[fifteen]

With the advent of computer generated drawings for manufacturing and machining, many symbols have fallen out of common use. This poses a trouble when attempting to interpret an older mitt-drawn document that contains obscure elements that cannot be readily referenced in standard didactics text or command documents such as ASME and ANSI standards. For example, ASME Y14.5M 1994 excludes a few elements that convey critical data as independent in older United states Navy drawings and shipping manufacturing drawings of World War 2 vintage. Researching the intent and meaning of some symbols tin can prove difficult.

Example [edit]

Example mechanical drawing

Hither is an example of an applied science drawing (an isometric view of the same object is shown in a higher place). The unlike line types are colored for clarity.

- Blackness = object line and hatching

- Carmine = hidden line

- Blue = heart line of slice or opening

- Magenta = phantom line or cut aeroplane line

Exclusive views are indicated by the direction of arrows, as in the example right side.

Legal instruments [edit]

An engineering cartoon is a legal document (that is, a legal instrument), because information technology communicates all the needed information about "what is wanted" to the people who will expend resource turning the idea into a reality. It is thus a part of a contract; the purchase club and the drawing together, also every bit any ancillary documents (engineering science change orders [ECOs], called-out specs), constitute the contract. Thus, if the resulting product is wrong, the worker or manufacturer are protected from liability every bit long as they have faithfully executed the instructions conveyed by the drawing. If those instructions were wrong, it is the mistake of the engineer. Because manufacturing and construction are typically very expensive processes (involving large amounts of capital and payroll), the question of liability for errors has legal implications.

Human relationship to model-based definition (MBD/DPD) [edit]

For centuries, technology cartoon was the sole method of transferring information from design into manufacture. In recent decades another method has arisen, called model-based definition (MBD) or digital product definition (DPD). In MBD, the information captured past the CAD software app is fed automatically into a CAM app (calculator-aided manufacturing), which (with or without postprocessing apps) creates code in other languages such every bit Grand-code to be executed by a CNC machine tool (estimator numerical control), 3D printer, or (increasingly) a hybrid machine tool that uses both. Thus today it is oftentimes the instance that the information travels from the mind of the designer into the manufactured component without having ever been codification by an engineering science drawing. In MBD, the dataset, non a drawing, is the legal musical instrument. The term "technical data package" (TDP) is now used to refer to the complete packet of information (in 1 medium or another) that communicates data from design to production (such equally 3D-model datasets, technology drawings, engineering change orders (ECOs), spec revisions and addenda, and so on).

It still takes CAD/CAM programmers, CNC setup workers, and CNC operators to do manufacturing, too as other people such as quality assurance staff (inspectors) and logistics staff (for materials treatment, shipping-and-receiving, and front office functions). These workers frequently employ drawings in the course of their work that have been produced from the MBD dataset. When proper procedures are being followed, a clear chain of precedence is always documented, such that when a person looks at a drawing, s/he is told by a note thereon that this drawing is not the governing instrument (because the MBD dataset is). In these cases, the drawing is still a useful certificate, although legally it is classified as "for reference simply", meaning that if any controversies or discrepancies arise, it is the MBD dataset, not the drawing, that governs.

Come across also [edit]

- Architectural drawing

- B. Hick and Sons – Notable drove of early locomotive and steam engine drawings

- CAD standards

- Descriptive geometry

- Document management system

- Engineering drawing symbols

- Geometric tolerance

- ISO 128 Technical drawings – General principles of presentation

- light plot

- Linear scale

- Patent cartoon

- Scale rulers: architect's scale and engineer's calibration

- Specification (technical standard)

- Structural drawing

References [edit]

- ^ a b Yard. Maitra, Gitin (2000). Applied Engineering Drawing. 4835/24, Ansari Route, Daryaganj, New Delhi - 110002: New Age International (P) Limited, Publishers. pp. ii–5, 183. ISBN81-224-1176-ii.

{{cite book}}: CS1 maint: location (link) - ^ a b Rolt 1957, pp. 29–thirty.

- ^ French & Vierck 1953, pp. 99–105

- ^ a b c French 1918, p. 78.

- ^ a b c French & Vierck 1953, pp. 111–114

- ^ French & Vierck 1953, pp. 97–114

- ^ French & Vierck 1953, pp. 108–111

- ^ French & Vierck 1953, p. 102.

- ^ Bertoline, Gary R. Introduction to Graphics Communications for Engineers (4th Ed.). New York, NY. 2009

- ^ United States Bureau of Naval Personnel. "Applied science Help i & C.". 1969. p. 188.

- ^ Andres G. Embuido. "Technology Assistance 1 & C". 1988. p. 7-10.

- ^ "Farm Planners' Engineering Handbook for the Upper Mississippi Region". 1953. p. 2-five.

- ^ Farhad Ghorani. "Title Block". 2015.

- ^ Paul Munford. "Technical drawing standards: Grid reference frame".

- ^ Brian Griffiths. "Engineering Cartoon for Manufacture". 2002. p. 1 and p. xiii.

Bibliography [edit]

- French, Thomas E. (1918), A manual of applied science cartoon for students and draftsmen (second ed.), New York, New York, USA: McGraw-Hill, LCCN 30018430. : Engineering Drawing (volume)

- French, Thomas East.; Vierck, Charles J. (1953), A manual of engineering drawing for students and draftsmen (8th ed.), New York, New York, USA: McGraw-Hill, LCCN 52013455. : Engineering science Drawing (volume)

- Rolt, L.T.C. (1957), Isambard Kingdom Brunel: A Biography, Longmans Green, LCCN 57003475.

Farther reading [edit]

- Basant Agrawal and C 1000 Agrawal (2013). Engineering Cartoon. 2nd Edition, McGraw Hill Education India Pvt. Ltd., New Delhi. [1]

- Paige Davis, Karen Renee Juneau (2000). Technology Drawing

- David A. Madsen, Karen Schertz, (2001) Engineering science Drawing & Design. Delmar Thomson Learning. [2]

- Cecil Howard Jensen, Jay D. Helsel, Donald D. Voisinet Computer-aided applied science drawing using AutoCAD.

- Warren Jacob Luzadder (1959). Fundamentals of applied science drawing for technical students and professional.

- One thousand.A. Parker, F. Pickup (1990) Engineering Drawing with Worked Examples.

- Colin H. Simmons, Dennis E. Maguire Manual of engineering drawing. Elsevier.

- Cecil Howard Jensen (2001). Interpreting Engineering Drawings.

- B. Leighton Wellman (1948). Technical Descriptive Geometry. McGraw-Loma Book Company, Inc.

External links [edit]

- Examples of cubes drawn in dissimilar projections

- Animated presentation of drawing systems used in technical drawing (Flash animation) Archived 2011-07-06 at the Wayback Motorcar

- Design Handbook: Applied science Drawing and Sketching, past MIT OpenCourseWare

Source: https://en.wikipedia.org/wiki/Engineering_drawing

0 Response to "descridomain_7 3d surfaces on engineering drawings"

Post a Comment